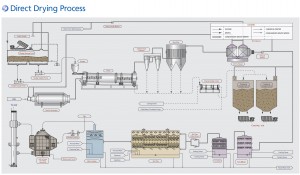

Enbiocon has designed a new and complete process for sludge treatment plant in Korea. The sludge coming from about 20 Waste Water treatment plants (WWTP) are dryed until they contain only 10 % of water. At this stage, sludge can be burnt and the energy spent for the drying is almost (90%) recovered.

We got in touch with Enbiocon during Pollutec show in Lyon in December 2012. Sludge management is one of the major environmental challenges facing water supply on Earth. In the past, sludge would be disposed in waste area and dried in open air, or loaded on boats and drawn in deep sea. Those 2 processes are, of course, dangerous for environment, and the habit of spreading the sludge on fields as fertilizer is better, but it has limits. The dry + burn process is the best thing to do – except for the energy consumption.

Strategy: France is the home land of 3 of the biggest water management companies in the world, Veolia, GDF-Suez and SAUR.

Actions :

- We identified contact in those 3 key accounts, set meetings and had process reviewed.

- We partnered with design companies, specialized distributors for industrial components.

- We approached several public services for water management. of et a potential partner list and submitted each contact to LISCA for approval.

- We identified decision makers, send LISCA company profile and invite them on the booth.

- During show, we attend the meetings for translation and support.

Results :

The R&D team of one of the key account visited the existing plant in Korea in order to initiate international partnership.

(Click on image for full size)

Go to Enbiocon website[spacer]

[button text=”contact us” link=”contacts#anglais” style=”default” size=”normal” target=”_self” display=”inline” icon=”no”][spacer]

(Click on link “references & history” bellow to access archive of similar posts)